Sunday 30th July 2023

We all know that working at height can be dangerous, so before climbing a ladder, entering an erial platform, or stepping onto a roof, you must be sure you have the appropriate fall protection equipment and that it is securely in place. Your life could depend on it.By ensuring you are using the correct equipment properly, as per the manufacturer’s recommendations, you can focus on the task at hand, secure in the knowledge that you are working safely. Using the appropriate equipment correctly may also add to your comfort. When you are working in any environment for long enough, it is easy to become accustomed to the risks and slightly less sensitive to the real danger you are in. This increases the risk of making mistakes. That’s human nature, which is why no amount of health and safety training is too much, especially as using PPE correctly in all circumstances can be complicated. With that in mind, we’ve compiled a list of the five most common mistakes that we’ve come across, so you can avoid them.

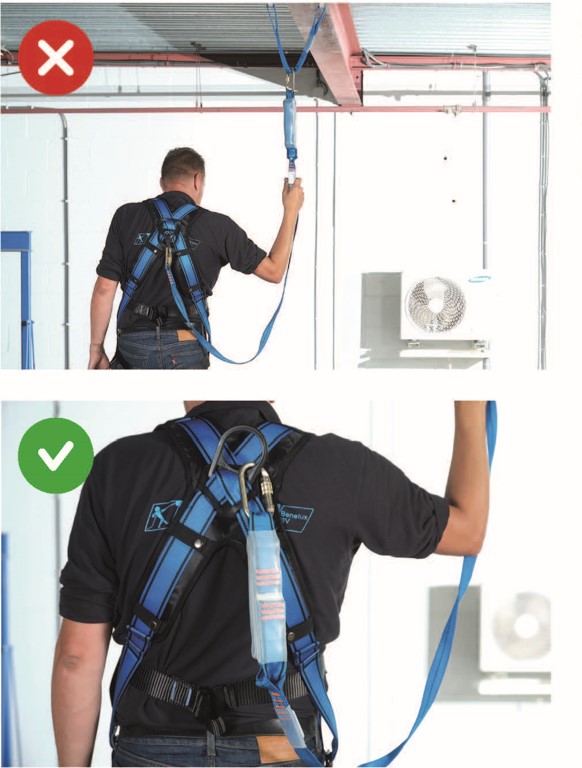

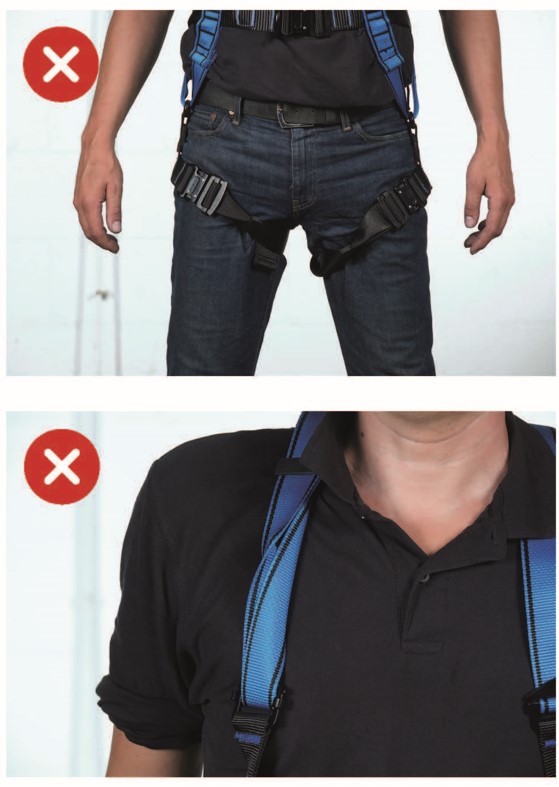

1.Poorly Fitted Harness

Putting on a safety harness looks straightforward, and many people are doing it right, but there are several common mistakes to look out for. Wearing an ill-fitting harness won’t provide adequate protection in the event of a fall, but it isn’t always obvious to the wearer that their harness is the wrong size. Loose harnesses are not secure and allow for the possibility of injury caused by the straps. They should be snugly fitted, but overly tight harnesses are uncomfortable and may restrict circulation, particularly in the legs. Twisted straps can injure, rather than protect, the wearer. A backplate that is too low may feel secure, but offers less support and could lead to severe injury in the lower back in the event of a fall. The best way to ensure someone is wearing the right harness for their body type is to consult the supplier’s size guide. Besides ensuring safety, a correctly fitted harness is more comfortable for the user, so they can focus for longer. A harness must also be attached properly to be effective, so for fall arrest, only use attachment points that are marked with A or A/2 to connect the harness to the attachment system. Remember that both A/2 attachment points must be utilised for complete fall protection. Attachment points without markings are used for rope-access or work positioning applications and should always be used with a fall arrest system attached to the A or A/2 attachment points. Two pairs of eyes are better than one, so getting someone else to check how a harness is attached makes dangerous oversights less likely.

Takeaway: Always consult the manufacturer’s size chart, and ask a colleague to check that the harness is adjusted and attached correctly before starting any height work.

- Wearing an ill-fitting harness won’t provide adequate protection in a fall.

- Loose harnesses are insecure and may lead to injuries caused by the straps.

- Harnesses should be snugly fitted but not overly tight to avoid discomfort and circulation issues.

- Twisted straps can be dangerous rather than protective.

- Backplate positioned too low can result in severe lower back injury during a fall.

- Consult the supplier's size guide to ensure the right harness for your body type.

- Correctly attach the harness using marked A or A/2 attachment points for fall arrest.

- Get someone else to double-check the harness attachment to avoid oversights.

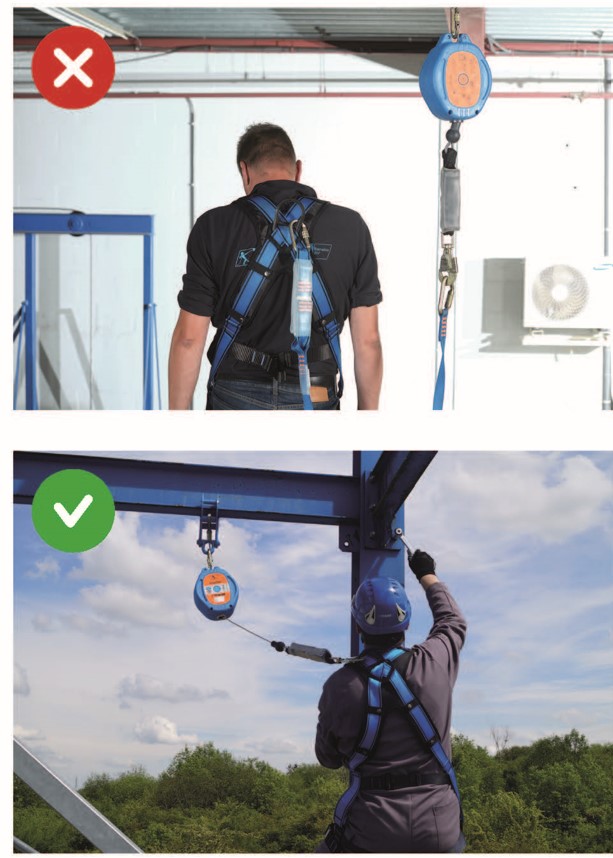

2. Wrong use of lanyards

When working at height, secure anchor points are not always immediately obvious, or connectors won’t fit onto the anchor points, so it’s not uncommon for people to loop their lanyards around the structure itself. This may feel secure and might even hold your weight if you are unfortunate enough to fall, but there’s no guarantee. The only way to know you are safe is to use certified and approved (mobile) anchor points that have been load tested. Using fall arrest equipment without a shock absorber will do nothing to minimise the impact of a fall and leaves people vulnerable to serious injury. Fall arrest equipment without an absorber can only be used for restraint and can’t be used in situations where a worker can fall. A shock absorber will be far less effective when it is connected to the structural anchor point rather than the harness.

Takeaway: Identify the tested, approved, and certified (mobile) anchor points before working at height. Always ensure a shock absorber is included and connected to the wearer rather than the attachment point.

- Avoid looping lanyards around structures; use certified and load-tested anchor points instead.

- Fall arrest equipment without a shock absorber is insufficient in minimizing fall impact.

- Ensure the shock absorber is connected to the wearer, not the attachment point.

3. Not Observing the Free Fall Space and Overlooking the ‘Pendulum Effect

The harness and lanyard are designed to protect the wearer from the impact of free-falling from a specific minimum height. If the lanyard is too long, the user is at risk of serious jolt-related or tangle-related injuries and the equipment may fail to prevent a free fall to the ground below. Another potential risk stems from the pendulum effect (swing-fall), which is the lateral movement or swing that happens during falls where the fall arrest system extends sideways from the normal fall line (perpendicular). This movement effectively increases the falling distance and exposes workers to the risk of swinging into nearby obstacles at dangerous speeds. It can also lead to potentially catastrophic consequences if the attachment system rubs against any sharp edges and loses integrity. The way to minimise these risks is to keep the fall arrest devices

Takeaway: Check the length of the lanyard, keep the angle between your fall arrest device and the anchor point to a minimum, and ensure you have enough free fall and swing space to prevent a collision in the event of a fall.

- Check lanyard length to prevent serious injuries due to excessive slack during a fall.

- Be aware of the pendulum effect, which increases falling distance and can lead to dangerous collisions.

- Keep the angle between your fall arrest device and anchor point to a minimum.

4. Combining Fall Arrest Equipment

Mixing and matching fall arrest equipment might seem like doubling up on safety precautions, but it is better to avoid this practice and stick to user manual guidelines. For example, using a guided type of fall arrester (EN353-2) as an anchor point for another fall arrest device. Or using a fall arrester with a lanyard to increase the freedom of movement.

Takeaway: Always read the user manual to ensure the products you’re using are compatible, and get professional advice if you’re still unsure.

- Avoid mixing different fall arrest equipment; follow user manual guidelines.

- Don't use a guided fall arrester as an anchor point for another device.

- Don't use a fall arrester with a lanyard to increase freedom of movement without proper guidance.

5. Not Checking the Condition of Safety Equipment

If safety equipment looks good at a glance, it’s easy to assume that it’s still in good condition; however, wear and tear is not always immediately obvious until it is too late. That’s why we recommend spending a few moments to visually inspect equipment before using it and in some cases, you should do a functional check as well. Also, ask a co-worker to double-check that your harness is fitted and adjusted correctly before starting any work. By taking an extra minute to inspect your equipment, you dramatically decrease the chances of a workplace accident occurring.

Takeaway: Never assume safety equipment is in good condition without inspecting it thoroughly, and get someone else to check it as well.

- Visually inspect safety equipment before use, as wear and tear might not be immediately obvious.

- Perform functional checks when necessary.

- Have a co-worker double-check your harness for proper fitting and adjustments.

- Never assume safety equipment is in good condition without thorough inspection.

Stay safe

You can never be too safe, and going the extra mile to ensure the safety of workers will not only help prevent accidents and injuries but will also show your workers and your clients that you care. It’s a win-win. Heights are perhaps the most dangerous of all workplace settings, and accidents can happen without warning at any moment, so we hope you’ve found the tips we’ve shared above useful. We are passionate about safety, so if you want to know more about working safely at height, we’re happy to help.